ब्लॉग

-

प्लॅस्टिक इंजेक्शन केलेला भाग वॉरपेज विकृत का आहे?

वॉरपेज विरूपण म्हणजे इंजेक्शन मोल्ड केलेल्या उत्पादनाच्या आकाराचे विकृतीकरण आणि वॉरपेज, भागाच्या आकाराच्या अचूकतेच्या आवश्यकतांपासून विचलित होणे, हे इंजेक्शन मोल्ड डिझाइन आणि उत्पादनातील दोषांपैकी एक आहे....पुढे वाचा -

इंजेक्शन प्लास्टिकच्या भागांचे मुख्य प्रक्रिया पॅरामीटर्स

इंजेक्शन मोल्डेड पार्ट्सचे मुख्य प्रक्रिया पॅरामीटर्स 4 घटकांमध्ये गटबद्ध केले जाऊ शकतात ज्यात समाविष्ट आहे: सिलेंडर तापमान, वितळलेले तापमान, इंजेक्शन मोल्ड तापमान, इंजेक्शन दाब.1.सिलेंडर तापमान: हे सर्वज्ञात आहे की प्लास्टिक इंजेक्शन मोल्ड केलेल्या भागांचे यश अनेकांवर अवलंबून असते ...पुढे वाचा -

TPE ओव्हरमोल्डिंग

1.ओव्हरमोल्डिंग म्हणजे काय ओव्हरमोल्डिंग ही इंजेक्शन मोल्डिंग प्रक्रिया आहे जिथे एक सामग्री दुसऱ्या सामग्रीमध्ये तयार केली जाते.येथे आम्ही प्रामुख्याने TPE ओव्हरमोल्डिंगबद्दल बोलतो.TPE ला थर्मोप्लास्टिक इलास्टोमर म्हणतात, हे रबर लवचिकता आणि प्लास्टिक sti दोन्हीसह एक कार्यात्मक सामग्री आहे...पुढे वाचा -

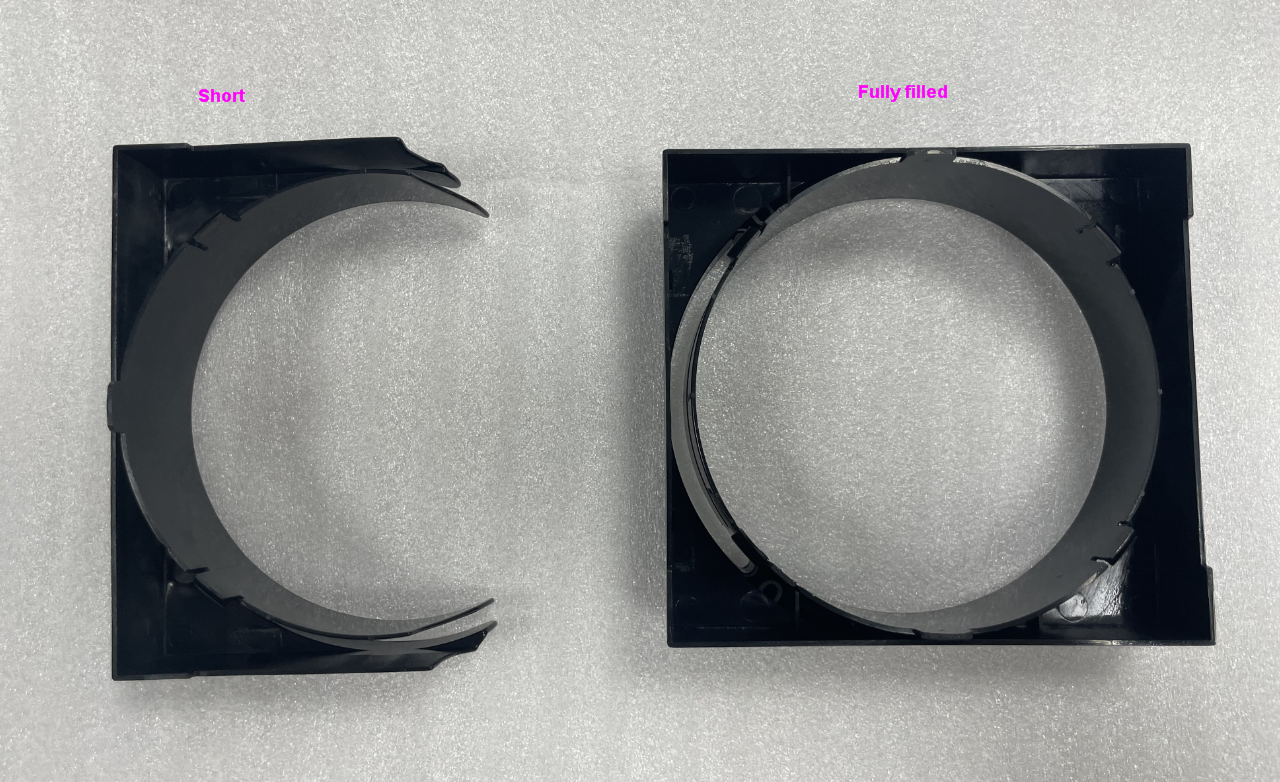

प्लास्टिकचा भाग पूर्णपणे का टोचला जात नाही?

इंजेक्शन मोल्डिंगमध्ये, शॉर्ट शॉट इंजेक्शन, ज्याला अंडरफिल देखील म्हणतात, आंशिक अपूर्णतेच्या घटनेच्या इंजेक्शनच्या प्लास्टिकच्या प्रवाहाच्या शेवटी किंवा मोल्डच्या पोकळीचा काही भाग भरलेला नाही, विशेषत: पातळ-भिंती असलेला भाग किंवा प्रवाहाचा शेवटचा संदर्भ देते. मार्ग क्षेत्र.वितळण्याची कामगिरी...पुढे वाचा -

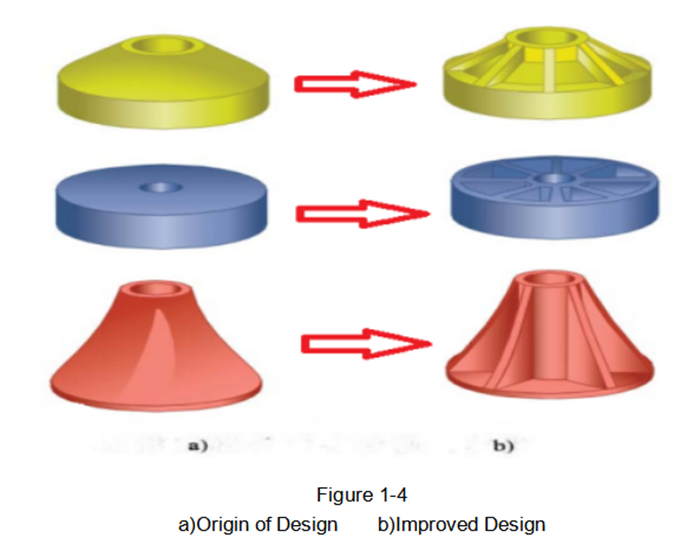

इंजेक्शन मोल्डिंग प्लास्टिक भागांची भिंत जाडी डिझाइन

प्लॅस्टिकच्या भागांच्या डिझाइनमध्ये, भागाच्या भिंतीची जाडी हा पहिला पॅरामीटर आहे ज्याचा विचार केला जातो, भागाची भिंतीची जाडी भागाचे यांत्रिक गुणधर्म, भागाचे स्वरूप, भागाची इंजेक्ट करण्याची क्षमता आणि किंमत निर्धारित करते. भागाचा.मी...पुढे वाचा -

वेगवान इंजेक्शन मोल्ड कधी वापरावे

ऍपिड इंजेक्शन मोल्डिंग हे एक बहुमुखी तंत्रज्ञान आहे ज्याचा उपयोग विविध भाग आणि उत्पादने तयार करण्यासाठी केला जाऊ शकतो.प्रक्रिया जलद आणि कार्यक्षम आहे आणि जटिल भूमितीसह भाग तयार करण्यासाठी वापरली जाऊ शकते.रॅपिड इंजेक्शन मोल्डिंग देखील प्रोटोटीसाठी एक आदर्श उपाय आहे...पुढे वाचा -

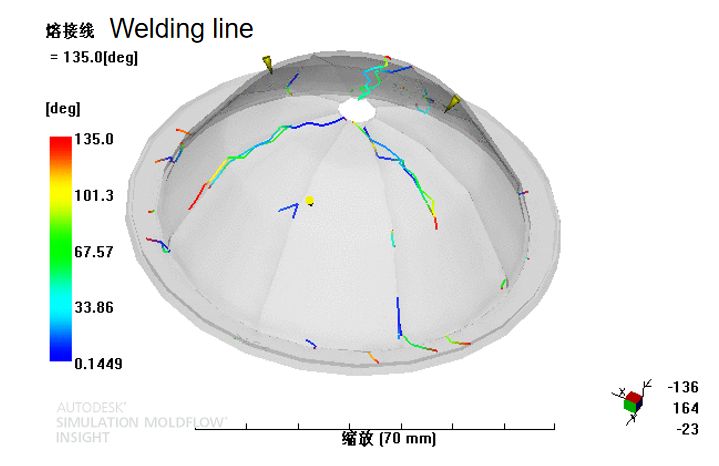

प्लास्टिक इंजेक्शन भाग-वेल्डिंग लाइन

वेल्डिंग लाइन म्हणजे काय वेल्डिंग लाइनला वेल्डिंग मार्क, फ्लो मार्क असेही म्हणतात.इंजेक्शन मोल्डिंग प्रक्रियेत, जेव्हा अनेक गेट्स वापरले जातात किंवा पोकळीमध्ये छिद्रे असतात, किंवा जाडीच्या परिमाणांमध्ये मोठ्या प्रमाणात बदल असलेले इन्सर्ट आणि उत्पादने असतात, तेव्हा प्लॅस्टिक वितळण्याचा प्रवाह साच्यामध्ये 2 di पेक्षा जास्त होतो...पुढे वाचा -

सानुकूल इंजेक्शन मोल्डिंग म्हणजे काय

इंजेक्शन मोल्डिंग ही एक प्रकारची उत्पादन प्रक्रिया आहे ज्यामध्ये वितळलेल्या सामग्रीला मोल्डमध्ये इंजेक्शन देऊन भाग किंवा उत्पादने बनविली जातात.इंजेक्शन मोल्डिंग विविध प्रकारच्या सामग्रीसह केले जाऊ शकते, परंतु सामान्यतः प्लास्टिकचा वापर केला जातो.सानुकूल इंजेक्शन मोल्डिंग ही एक प्रक्रिया आहे ज्यामध्ये प्लास्टिकला मीटरमध्ये इंजेक्शन दिले जाते...पुढे वाचा -

प्लॅस्टिक इंजेक्शन मोल्ड उत्पादनापूर्वी तुम्हाला अधिक जाणून घ्यायचे आहे

प्लॅस्टिक इंजेक्शन मोल्ड उत्पादनावरील प्रश्न प्रश्न: अंतिम पेमेंट पूर्ण झाल्यावर टूलिंग आमच्याकडे असेल याची तुम्ही पुष्टी करू शकता?रुईचेंग उत्तर : साचे कोणाच्या मालकीचे आहेत त्यांना कोण पैसे द्यायचे हा नेहमीच नियम आहे.आम्ही फक्त निर्माता आहोत ...पुढे वाचा -

इंजेक्शन मोल्डच्या शॉट लाइफची व्याख्या

इंजेक्शन मोल्ड हे औद्योगिक उत्पादनासाठी मुख्य प्रक्रिया उपकरणे आहेत, प्लास्टिकचे भाग तयार करण्यासाठी मोल्डचा वापर, उत्पादन कार्यक्षमता प्रदान करणे, गुणवत्ता सुनिश्चित करणे सोपे, कमी उत्पादन खर्च...पुढे वाचा -

प्लॅस्टिक इंजेक्शन मोल्डच्या खर्चावर कोणते घटक परिणाम करतात

'इंजेक्शन मोल्डच्या किमतीवर कोणते घटक परिणाम करतात' हे समजून घेणे महत्त्वाचे आहे. घटक जाणून घेतल्याने तुम्हाला तुमच्या डिझाईनसाठी आवश्यक टूलिंग समजण्यास मदत होईल आणि तुमच्या प्रोजेक्टसाठी व्यावसायिक पुरवठादार निवडण्यात मदत होईल, खालीलपैकी काही मुख्य आहेत कारणे: 1. डिझाइन पूर्ण...पुढे वाचा